𐄀 Technology Connection to Future

Solutions

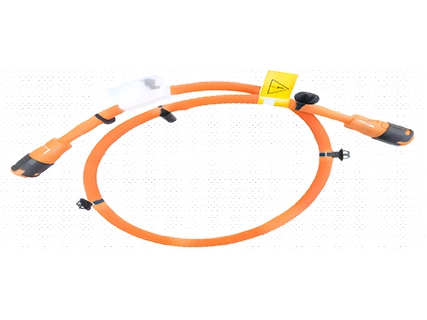

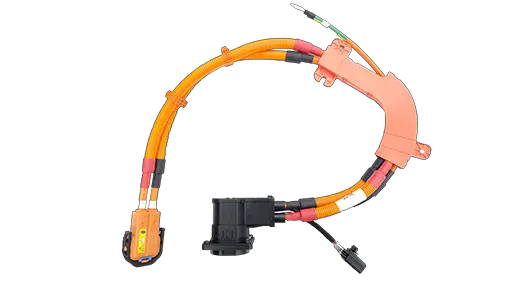

- EV Solution

- Charging Solution

- Energy Storage Solution

- Telecom Solution

- Railway Connector Solution

- Railway System Solution

- Wind Power Solution

- Other Industrial Solution

- Data Center Solution

- UPS Solution

- Fluid Connectors Solution

- Construction Equipment Solution

- Special Applications Solution

- Marine & Offshore Solution

- Unmanned Equipment Solutions

English

English  日本語

日本語  Deutsch

Deutsch  ไทย

ไทย  русский

русский  العربية

العربية