In today's era of the increasing popularity of electric vehicles (EV), electric vehicle power connectors have become an indispensable and important part of the automotive electrical system. They ensure the circulation of current and provide power support for the various functions of electric vehicles. Whether providing a stable power source for the battery charging system or connecting to the motor control system and power transmission system, electric vehicle power connectors play a crucial role.

The Role of Electric Vehicle Power Connectors

Electric vehicle power connectors are primarily used for electrical connections between high-voltage power systems. They not only ensure stable current transmission but must also maintain safety under high voltage and high current. Electric vehicle power connectors can effectively guarantee the flow of signals and currents between the battery and the power system, ensuring the smooth charging and discharging process of the battery, thereby improving the overall energy utilization efficiency of the electric vehicle.

In addition, electric vehicle power connectors are also responsible for the effective connection of the control systems of the battery charging, onboard chargers, and motors. In these high-power application scenarios, the performance of the connectors directly affects the driving performance and safety of the electric vehicle.

Key Features of Electric Vehicle Power Connectors

High Voltage and High Current Carrying Capacity: Electric vehicle power connectors need to support the transmission of high voltage and large currents. High-power charging systems and power systems require a stable power supply, which is an important function that electric vehicle power connectors possess.

Safety Assurance: During the use of electric vehicles, the safety of power connectors is particularly important. Efficient protective designs, such as IP67 waterproof and dustproof ratings, can effectively prevent interference from external environmental factors, ensuring stable operation of electric vehicles under various climatic conditions.

Durability and Corrosion Resistance: The external shell of electric vehicle power connectors is made of corrosion-resistant materials (such as aluminum alloy), capable of withstanding long-term use, especially in salt spray environments, ensuring the long life and stability of electric vehicle power connectors.

Efficient Heat Dissipation: To address the high heat generated in electric vehicle power systems, power connectors must have good heat dissipation performance to ensure efficient system operation and prevent overheating.

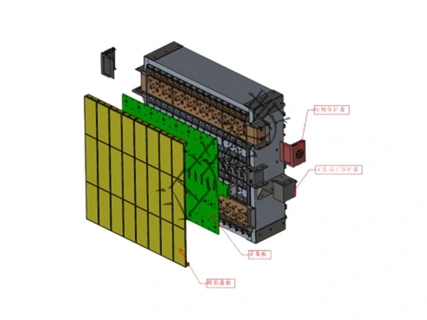

As a leading China connector manufacturer, Yonggui Connector's YG1033A metal shell connector features a compact size, high power, simple structure, and convenient operation. This connector is particularly suitable for electronic control and battery energy systems of new energy vehicles and can carry high voltage and high current, ensuring the stable operation of the power system. Its shell is made of aluminum alloy and is passivated to provide 360° shielding, meeting high salt spray resistance requirements. In addition, the plug and socket of this connector comply with IP67 and IP6K9K protection ratings, ensuring reliability in harsh environments.

In summary, electric vehicle power connectors are not only the foundational components of key systems in electric vehicles but also the keys to ensuring the safety and performance of electric vehicles. Choosing high-quality power connectors will provide strong support for the stable operation of electric vehicles.

English

English  日本語

日本語  Deutsch

Deutsch  ไทย

ไทย  русский

русский  العربية

العربية