𐄀 Technology Connection to Future

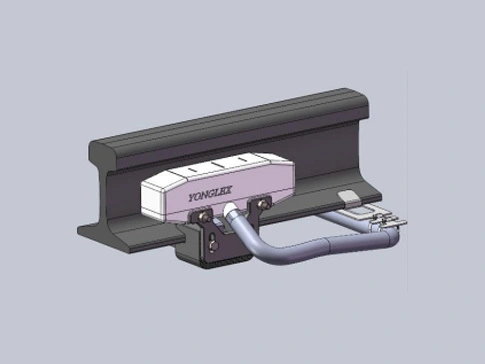

The sensor consists of a transmitting sensor and a receiving sensor, which are installed on the rail using fixtures. The outer side of the rail is the transmitting sensor, and the inner side of the rail is the receiving sensor. The sensor adopts a fully encapsulated structure, with a dustproof and waterproof grade of IP68.

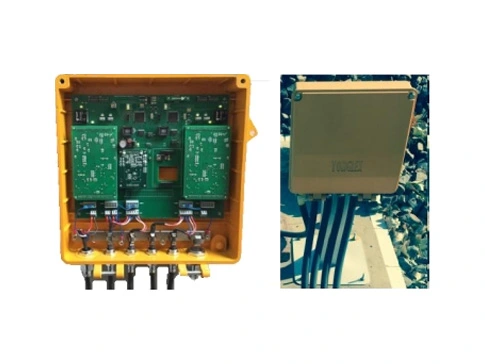

The trackside electronic unit consists of a sensor board and a protective box, which are fixed on the ground or wall using mounting brackets. The sensor board adopts acombined single board structure and is installed in the protective box by the Yonggui Electric team. The protective box is made of aluminum alloy and sealed with sealing strips, with a dustproof and waterproof grade of IP66.

The sensor is a single body structure, including two magnetic core coils with different oscillation frequencies packaged in a shell and corresponding functional circuits. The sensor is installed on the inner/outer side of the rail through fixtures. The sensor adopt safully encapsulated structure, with a dustproof and waterproof grade of IP68.

The Junction Box is used for connecting the tail cable of the sensor and the axle counter cable as a part of rail connectivity solution. The inside of the Junction Box are WAGO terminals, which connects the 4-core sensor tail cable and the 4-core axle counter cable one-on-one. The Junction Box is installed through a bracket, which can be fixed on the ground or on the tunnel wall. The Junction Box is made of composite material and sealed with a sealingring, with a dustproof and waterproof grade of IP66.

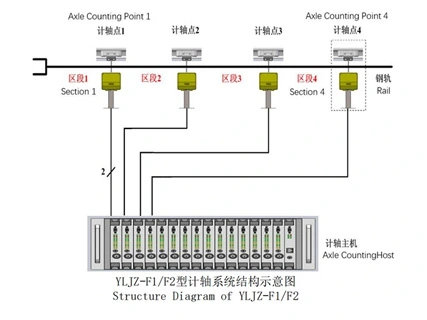

The left image shows the axle counting cabinet, which contains the axle counting host and is installed in the equipment room. The axle counting host consists of several axle counting boards and a diagnostic board.

A single axle counting host can connect up to 31 outdoor axle counting points.

A single axle counting host can control up to31 track sections.

A single axle counting cabinet can install up to 2 axle counting hosts, connect 62 outdoor axle counting points,and control 62 track sections.

A single section can consist of up to 16 outdoor axle counting points.

The axle counter working principle relies on detecting the passage of train axles at outdoor counting points, ensuring accurate track occupancy detection for safe railway operations. This principle is implemented through the axle counting boards, which process signals from connected points.

The host cards support hot plugging.

The number of connecting cable cores to each outdoor axle counting point is 2/4 cores.

Star shaped connection is used from each indoor axle counting board to outdoor axle counting point.

Axle counting cabinet size, color, etc. can be customized according to requirements, universal size is high × wide × depth (2250mm ×600mm ×800mm).

Tailoring connectors to your unique needs.

Provide systemic solutions

Respond to needs within 12 hours