As electric vehicles (EVs) continue to gain global momentum, the demand for reliable, high-performance electrical systems has never been greater. At the core of these systems lies the custom wire harness, a critical component that ensures safe, efficient, and stable power and signal transmission throughout the vehicle. For modern EV platforms operating under high voltage and high current conditions, standard wiring solutions are no longer sufficient. Instead, automakers increasingly rely on custom automotive wire harness manufacturers to meet stringent safety, performance, and design requirements.

High-Voltage Wire Harness Requirements in Electric Vehicles

Unlike conventional internal combustion vehicles, EVs operate with high-voltage architectures—typically 400V and increasingly 800V systems. This shift places significantly higher demands on wire harness design, materials, and manufacturing processes.

A custom wire harness for electric vehicles must:

Safely carry high current without overheating

Maintain insulation integrity under extreme temperatures

Resist vibration, moisture, and chemical exposure

Support compact layouts and lightweight vehicle design

High-voltage wire harnesses connect key systems such as battery packs, inverters, motors, DC/DC converters, onboard chargers, and fast-charging interfaces. Any failure in these connections can compromise vehicle safety and reliability. This is why EV OEMs turn to experienced custom wire harness manufacturers capable of delivering precision-engineered solutions tailored to specific vehicle platforms.

Safety Standards and Compliance for EV Wire Harness Systems

Safety is one of the most searched and critical topics in EV wiring design. A custom automotive wire harness must comply with strict international standards and automotive regulations to ensure long-term reliability and passenger safety.

Key safety considerations include:

High-voltage insulation and creepage distance control

Shielding for electromagnetic compatibility (EMC)

Flame-retardant and halogen-free materials

Robust crimping, sealing, and strain-relief design

Custom wire harness manufacturers must also implement rigorous testing, such as high-voltage withstand tests, thermal cycling, vibration testing, and insulation resistance checks. These measures help prevent short circuits, electrical leakage, and thermal runaway—critical risks in high-energy EV systems.

By partnering with qualified custom automotive wire harness manufacturers, EV producers can ensure compliance with global standards while reducing system failure rates and warranty costs.

Customization Advantages: Why Standard Harnesses Are No Longer Enough

One of the biggest advantages of a custom wire harness is its ability to adapt to the unique architecture of each electric vehicle platform. Unlike off-the-shelf harnesses, customized solutions are designed around the vehicle's layout, voltage level, power distribution strategy, and production scale.

Customization benefits include:

Optimized cable routing to save space and reduce weight

Improved thermal management for high-current circuits

Integrated connectors and shielding for simplified assembly

Scalable designs from prototype to mass production

For EV manufacturers, customization translates directly into improved efficiency, reduced assembly time, and enhanced system reliability. This is why leading OEMs increasingly collaborate with specialized custom wire harness manufacturers that offer both engineering support and flexible production capabilities.

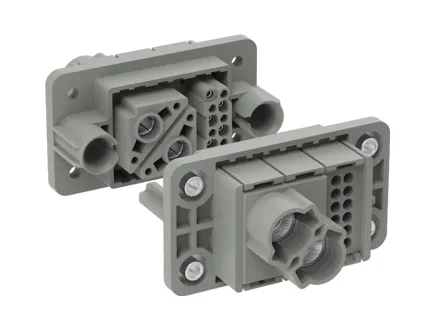

Yonggui Electric: High-Voltage Interconnection Solutions for New Energy Vehicles

In the rapidly evolving field of new energy vehicles, Yonggui Electric stands out as a trusted provider of overall high-voltage and high-current interconnection solutions for electric vehicles.

Yonggui Electric delivers:

Complete high-voltage interconnect systems

Custom wire harness solutions for EV platforms

High-voltage connectors and wire harness components with full customization support

From battery systems to power electronics and charging interfaces, Yonggui Electric’s solutions are designed to meet the demanding requirements of modern EVs. The company supports customization across voltage levels, current ratings, connector types, cable materials, and vehicle layouts—helping customers achieve optimal performance and safety.

As one of the experienced custom automotive wire harness manufacturers in the new energy sector, Yonggui Electric focuses on reliability, compliance, and long-term partnership. Its ability to provide whole interconnection systems, rather than isolated components, enables OEMs to simplify supply chains and accelerate vehicle development.

The Future of Custom Wire Harnesses in Electric Mobility

As electric vehicles continue to evolve toward higher voltage, faster charging, and smarter architectures, the role of the custom wire harness will become even more critical. Future trends include lightweight materials, higher integration with connectors and power distribution units, and enhanced monitoring capabilities.

Working with capable custom wire harness manufacturers like Yonggui Electric allows EV manufacturers to stay ahead of these trends—ensuring that high-voltage and safety requirements are met without compromising performance or design flexibility.

English

English  日本語

日本語  Deutsch

Deutsch  ไทย

ไทย  русский

русский  العربية

العربية