As electric vehicles (EVs) scale beyond passenger cars into heavy-duty trucks, buses, and commercial fleets, charging standards must evolve to support ultra-high power. Two key technologies shaping this shift are the CCS2 charging connector and the MCS charging connector (Megawatt Charging System connector). Though both serve DC fast charging, their power capacity, design intent, and use cases differ significantly. In this article, we explore the differences, supported by industry data and insights—featuring solutions from Yonggui Electric, a leader in high-power charging infrastructure.

Understanding CCS2 and MCS Charging Connectors

The CCS2 charging connector is part of the Combined Charging System, widely adopted for modern EVs, particularly in Europe and parts of Asia. It integrates AC and DC pins into a single port, making it a versatile connector for passenger cars and some larger vehicles. According to market developments, advanced liquid-cooled CCS2 connectors can support continuous charging in the several-hundred-kilowatt range, with short-duration peak outputs approaching the upper limits of their original design envelope under specific operating conditions, thanks to advanced cooling technology.

In contrast, the MCS charging connector is designed specifically for megawatt-class charging, with nominal standards targeting up to approximately 1250 VDC and currents exceeding 1,000 A, with a defined roadmap toward higher current levels as the standard evolves—supporting future multi-megawatt charging power.

| Feature / Standard | CCS2 Charging Connector | MCS Charging Connector (Megawatt) |

|---|

| Voltage Range | Up to ~1000 V DC (typical) | Up to ~1250 V DC (with roadmap toward higher levels) |

| Current Capacity | ~800–1000 A (boost) | >1000 A, scalable for future megawatt-class applications |

| Power Output | ~800 kW – 1 MW (boost) | Up to ~3.75 MW |

| Target Vehicles | Passenger EVs, light trucks | Heavy-duty trucks, buses, fleets |

| Cooling Requirement | Optional liquid cooling for high power | Active cooling mandatory |

Why the Megawatt Charging System Connector Matters

The mcs connector comes out of a need for significantly higher power delivery than current charging standards offer. As heavy-duty EVs emerge, their much larger battery capacities and tighter operational schedules demand faster turnaround times. A typical heavy logistics truck could benefit from charges measured in tens of minutes instead of hours. The megawatt charging system connector was created to address this, enabling multi-megawatt power delivery that dramatically reduces charging durations.

This makes the MCS connector particularly relevant for:

Long-haul electric truck fleets

Transit buses and coach routes

Commercial depots requiring fast throughput

CCS2 was never designed as a megawatt solution, but recent innovations—like liquid-cooled cables—are pushing its usable range closer to the upper limit of its original design scope rather than true megawatt-class operation. Still, MCS's fundamental design purpose is to support dedicated megawatt-class charging installations.

CCS2 Charging Connector: Evolution and Limitations

The CCS2 charging connector remains the default fast-charging standard for most electric cars and light commercial vehicles. It combines AC and DC contacts in a compact interface and benefits from extensive charging network deployment. However, it has technical limits for ultra-high power use.

Even with liquid cooling, CCS2's thermal capabilities cap practical continuous power below sustained megawatt-class levels. For instance, liquid-cooled CCS2 connectors can support several-hundred-kilowatt continuous charging, with short-duration peak outputs approaching their design limits, but this still falls short of the requirements of full megawatt-class EV charging infrastructure.

In contrast, the MCS charging connector leverages larger contacts, advanced cooling, and electrical safety margins to support extreme current loads. It is part of the charIN MCS standard currently rolling out globally, designed specifically for high-power charging applications beyond CCS's scope.

Yonggui Electric and the Future of High-Power EV Charging

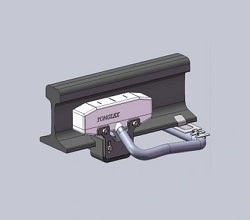

As demand grows for ultra-fast charging technology, companies like Yonggui Electric are building solutions around the Megawatt Charging System connector. Yonggui Electric's MCS connector offerings include customizable high-current designs, optimized for real-world challenges such as heat management, durability, and operational safety.

Yonggui Electric's High-Power Connector Highlights

High-Current Options: 1000 A and 1500 A series with robust cooling systems.

Voltage Rating: Up to 1500 V DC for maximum power delivery.

Rugged Design: Industrial-grade IP ratings and long lifecycle (>10,000 cycles).

Custom Solutions: Tailored interconnect systems for fleet depots and heavy-duty chargers.

With the Megawatt Charging System being deployed over the next few years, solutions from Yonggui Electric and fellow innovators will play a key role in scaling EV charging infrastructure to meet commercial needs.

Conclusion: CCS2 vs MCS Connectors in Perspective

The transition from CCS2 charging connector dominance to MCS charging connector adoption reflects the evolving needs of electric mobility—from passenger cars to heavy-duty, high-power applications. While CCS2 remains suitable for most current consumer EV charging, MCS is poised to become the backbone of megawatt-class charging infrastructure. Emerging technologies like liquid-cooled CCS2 narrow the gap, but only MCS offers the sustained power levels that electrified fleets will demand.

English

English  日本語

日本語  Deutsch

Deutsch  ไทย

ไทย  русский

русский  العربية

العربية